Polyester Wipes, Polyester Wipers

POLYESTER WIPER Series

100% Polyester high performance knitted cleanroom wipers

「DX WIPER series」 Polyester Cleanroom Wipers

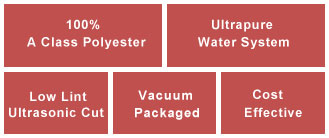

Features

Double knitted from 100% A class continuous polyester filament with ultrasonic trim – edge seal to prevent fiber and particle release, cost-effective and washed by ultrapure water system, ideal for wiping interior/exterior of process tools and cleaning critical environmental surface in cleanroom.

Main Applications

- Wiping and cleaning in cleanroom.

- Wiping all kinds of facilities.

Properties

| Item | Water Absorption | Wear Resistanc | Weave | Material | Texture | Weight (g/m²) | Thickness (mm) |

|---|---|---|---|---|---|---|---|

| JS155 | Good | Normal | Circular knitted | Polyester | Double plain | 100 | 0.42±0.02 |

| JS180 | Good | Good | Circular knitted | Double plain | 115 | 0.45±0.02 | |

| PK165 | Good | Normal | Circular knitted | Double textured | 105 | 0.45±0.02 | |

| PK200 | Good | Good | Circular knitted | Double textured | 130 | 0.5±0.02 | |

| LK240 | Good | Good | Circular knitted | Double textured | 150 | 0.52±0.02 | |

| CK260 | Great | Good | Circular knitted |

Polyester +Nylon |

Double textured | 165 | 0.48±0.02 |

| CK80 | Great | Good | Circular knitted | Double textured | 132 | 0.48±0.02 |

**These data are just for reference only

Size and package

| Item |

Size |

Edge |

Class | Package | Type |

|---|---|---|---|---|---|

| JS155 |

9"x9"(Nomal Size) |

ultrasonic |

Class 10~Class 10,000 |

Stacked/Bulk |

Economical |

| JS180 |

Advanced |

||||

| PK165 |

Economical |

||||

| PK200 |

Advanced |

||||

| LK240 |

Advanced |

||||

| CK260 | laser |

Advanced |

|||

| CK80 |

Advanced |

**Special specification can be custom-made.

*Class reference guideline

| FS 209 | 10 | 100 | 1,000 | 10,000 |

|---|---|---|---|---|

| ISO 14644-1 | Class 4 | Class 5 | Class 6 | Class 7 |

| GMP | - | A | B | C |

Feel relieved and high quality production process

| Production Process | |

|---|---|

Textile weaving  |

|

Dyeing and split  |

|

Cut and sealed edge  |

|

|

Washed by ultrapure water |

|

Inspection and package   |

|